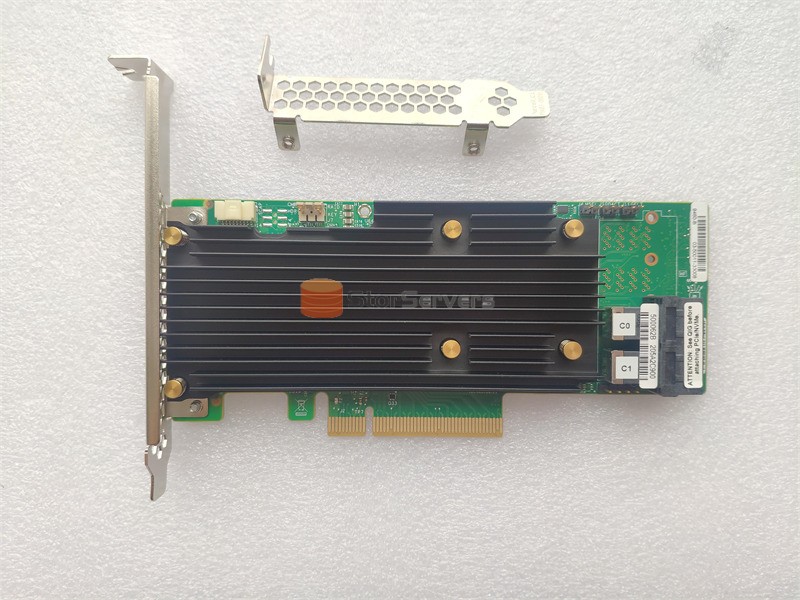

Maximize Efficiency with 9460-8i—Experience faster data management and file access.

- Manufacturer Part #: 05-50011-0223

- Ports: 8 internal23

- Connectors: Two (x4) SFF-864323

- Storage Interface Support: SAS, SATA, PCIe (NVMe)23

- Max PCIe (NVMe) Direct Attach Devices: Two x4, Four x223

- Max Devices Per Controller: SAS/SATA: 240; NVMe: 242

- Cache Memory: 2 GB 2133MHz

The 9460-8i is a high-performance RAID card that offers many advantages, making it an ideal choice for data storage and processing. The following is an introduction to several main advantages of lsi megaraid 9460 8i:

- Powerful performance: 9460-8i adopts advanced storage technology and processing capabilities, and provides excellent data transfer speed and processing performance by supporting PCIe 3.1 x8 interface.

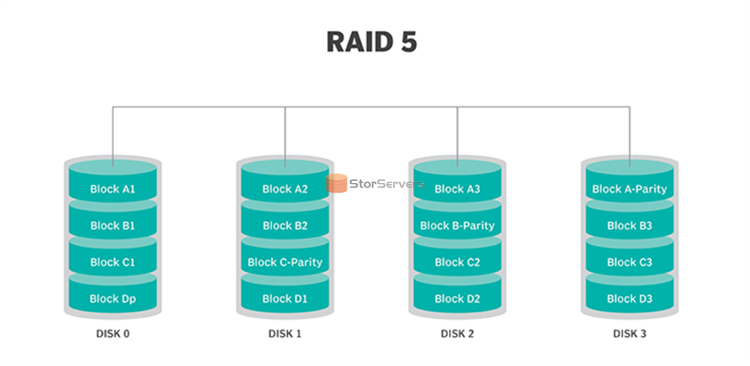

- High reliability: 9460-8i integrates RAID function, which can realize data backup and recovery according to needs, providing data protection and fault tolerance.

- Flexible storage management: 9460-8i provides rich storage management functions. Users can easily manage storage devices, create logical disks, set up hot spares and global hot spares, and monitor disk status and performance.

- Data protection and security: 05 50011 02 9460-8i uses advanced encryption algorithms and key management to encrypt data during transmission and storage to prevent data leakage and unauthorized access.

- Compatibility and scalability: In addition, it also provides a variety of expansion options, supporting multiple hard disk interfaces and external storage expansion to meet the storage needs of different application environments.

In general, as a high-performance RAID card, 9460-8i has powerful performance, high reliability, flexible storage management, data protection and security, as well as wide compatibility and scalability. These advantages make it an ideal choice for the storage needs of large enterprises, providing excellent data processing and protection capabilities.

STOR Technology Limited provides you with high-quality Raid Card, HBA Card, Hard Disk Drive, etc. We provide you with higher-quality services and assured after-sales service. Welcome to visit us and discuss related products with us.

Our website: https://www.cloudstorserver.com/

Contact us: alice@storservers.com / +86-755-83677183

Whatsapp : +8613824334699