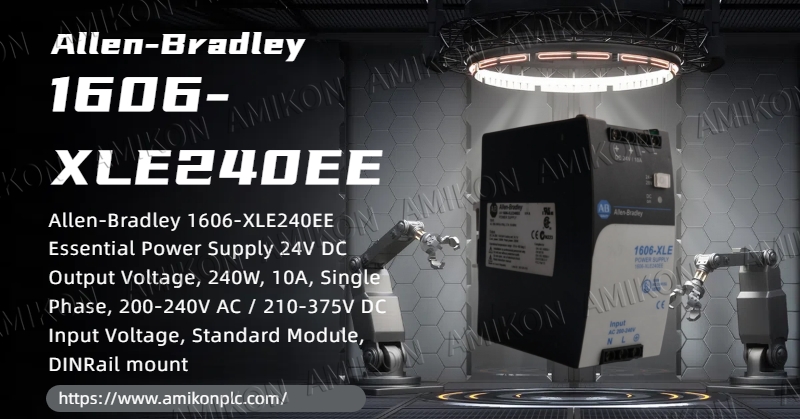

1606-XLE240EE power module reliable guarantee for stable operation of industrial equipment

1. Product Overview: Industrial-grade power solution

1606-XLE240EE is a high-performance power module designed for industrial environments, which can provide stable and reliable power support for various automation equipment. This power module adopts advanced switching power supply technology, with the characteristics of high efficiency and low energy consumption, and is suitable for various harsh industrial application scenarios.

Input voltage range: 85-264V AC (47-63Hz)

Output voltage: 24V DC

Rated power: 240W

Operating temperature range: -25°C to +70°C

Protection level: IP20

(1) Excellent reliability

The module adopts industrial-grade components and a sturdy metal shell design to ensure stable operation in harsh environments such as vibration and impact, with a mean time between failures (MTBF) of more than 100,000 hours.

(2) High efficiency and energy saving

The conversion efficiency is as high as 94%, which significantly reduces energy consumption and operating costs, and meets the strict requirements of modern industry for energy efficiency.

(3) Comprehensive protection functions

It has multiple safety mechanisms such as overload protection, short circuit protection, overvoltage protection and overheating protection, which effectively protects connected devices from power anomalies.

(4) Flexible installation method

Supports DIN rail installation and wall mounting, which is convenient for deployment in various industrial control cabinets.

(1) Industrial automation control system

Provides stable power supply for control equipment such as PLC, HMI, servo drive, etc. to ensure continuous and reliable operation of production lines.

(2) Mechanical processing equipment

Applicable to power supply for CNC machine tools, cutting machines, packaging machines and other equipment to ensure processing accuracy and production efficiency.

(3) Process control industry

Plays an important role in DCS systems in the fields of petrochemical, electric power and energy, and provides clean power for key control loops.

(4) Infrastructure field

Widely used in building automation, traffic signal systems and other occasions that require long-term stable operation.

4. Customer Case: Successful Application in an Automobile Manufacturing Plant

Background: The original power supply system of a large domestic automobile manufacturing plant frequently experienced voltage fluctuations, resulting in multiple shutdowns of the production line.

Solution: Use 1606-XLE240EE power modules to replace old equipment and build a distributed power supply system.

Results:

- Power failure rate reduced by more than 90%

- Production line downtime reduced by 85%

- Annual energy saving of about 150,000 yuan

- Maintenance costs significantly reduced

5. Installation and use guide

(1) Installation precautions

- Ensure that the installation environment is well ventilated

- Retain sufficient heat dissipation space (it is recommended to leave 50mm above and below)

- Use strictly in accordance with the rated load

- Regularly check whether the connection terminals are loose

- Clean the heat dissipation holes every quarter

- Monitor the operating temperature

- It is recommended to conduct a comprehensive inspection every 2 years

- No output: Check the input power and fuse

- Overheat alarm: Check the heat dissipation conditions and load conditions

- Output voltage is unstable: Check whether the load exceeds the rated range

Conclusion: The smart choice for industrial power supply

The 1606-XLE240EE power module has become a benchmark product in the field of industrial power supply with its excellent reliability, high efficiency and energy saving, and comprehensive protection functions. With the rapid development of Industry 4.0 and intelligent manufacturing, this module provides solid power guarantee for various industrial equipment, helping enterprises achieve efficient and stable production operations.

Get a quick quote

Manager: Leonia

Email:sales11@amikon.cn

Whatsapp: +8618030175807